Table of contents

• WHAT TO CONSIDER WHEN CHOOSING A DIAMOND BLADE

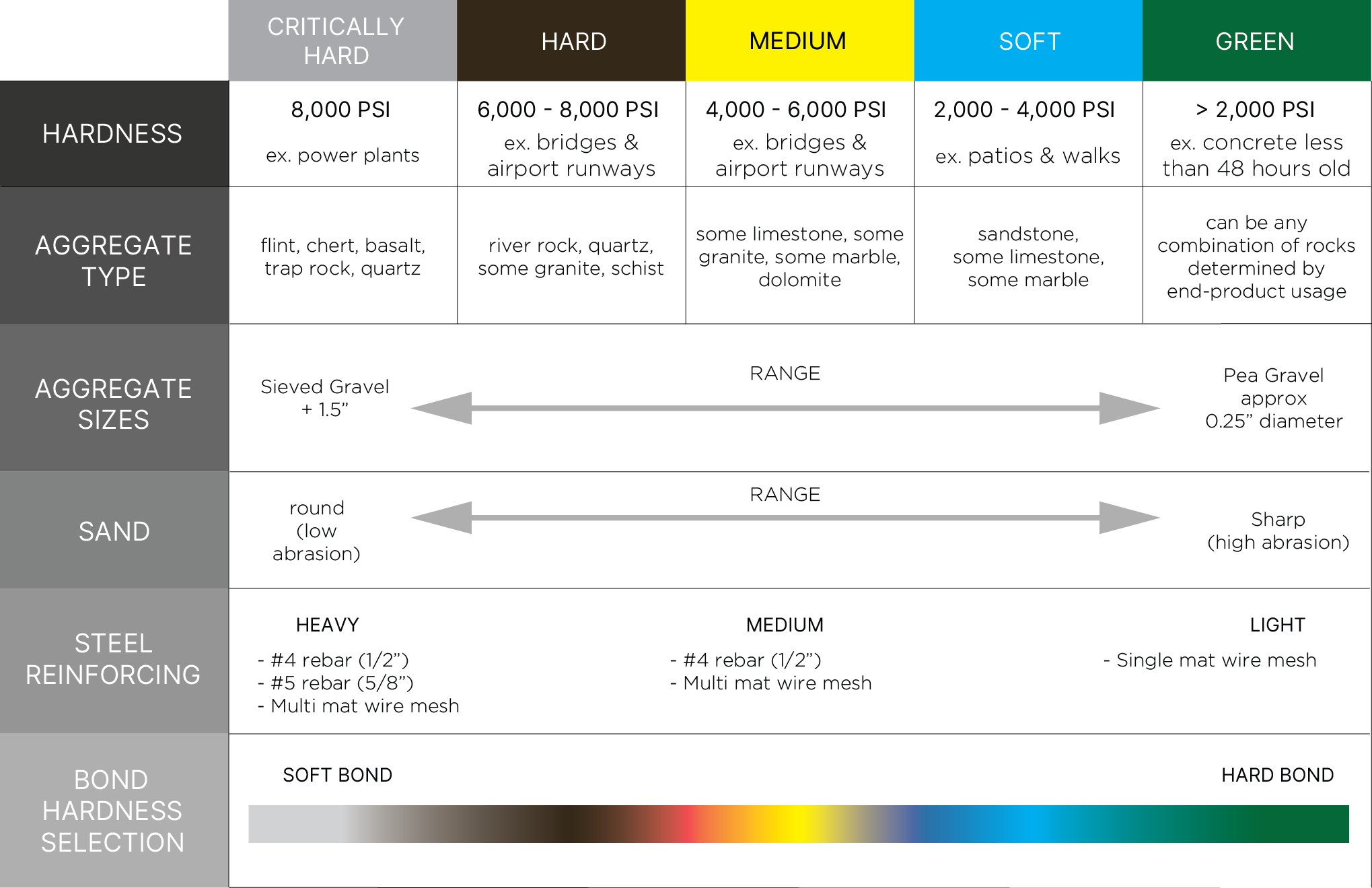

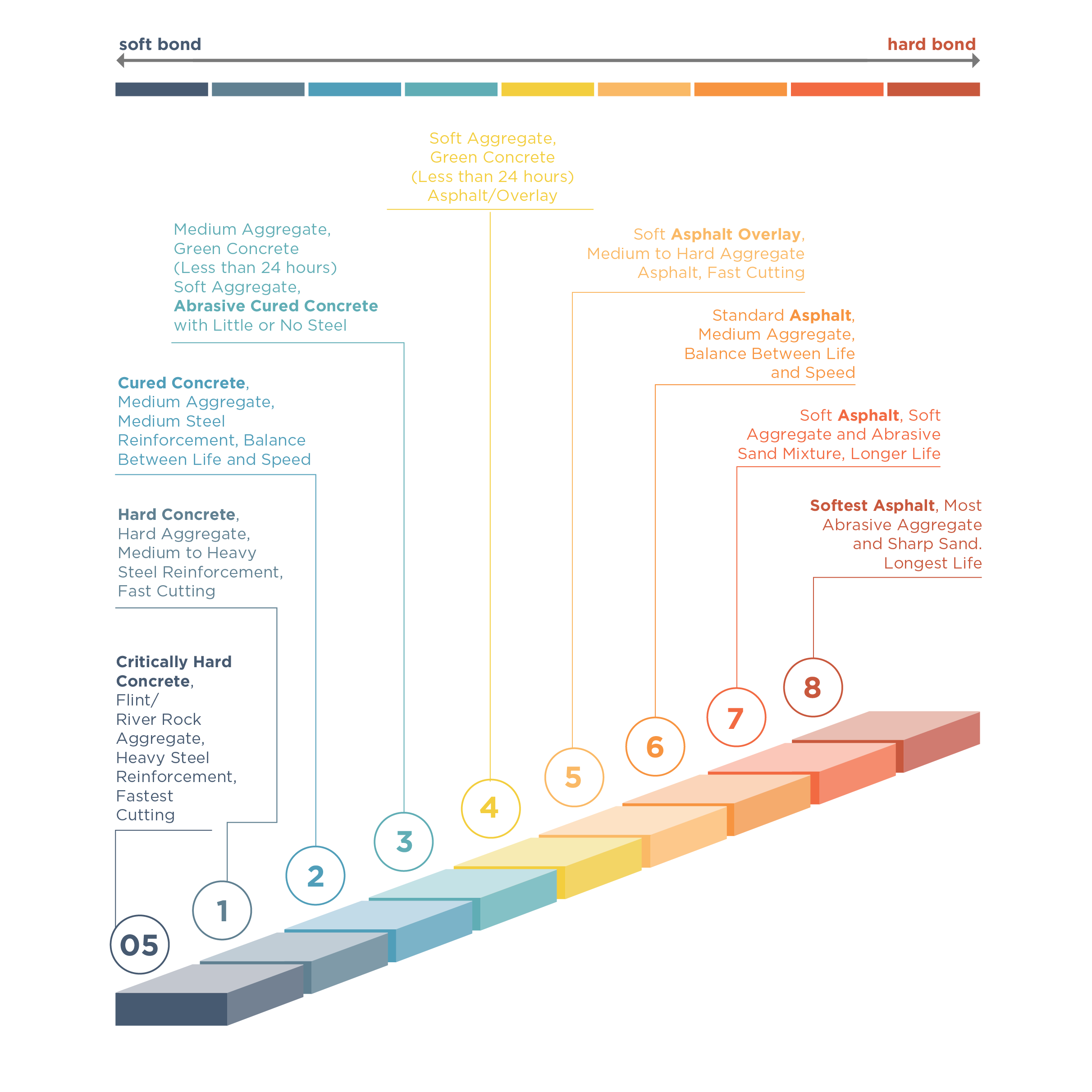

• AGGREGATE HARDNESS TO BOND RELATIONSHIP

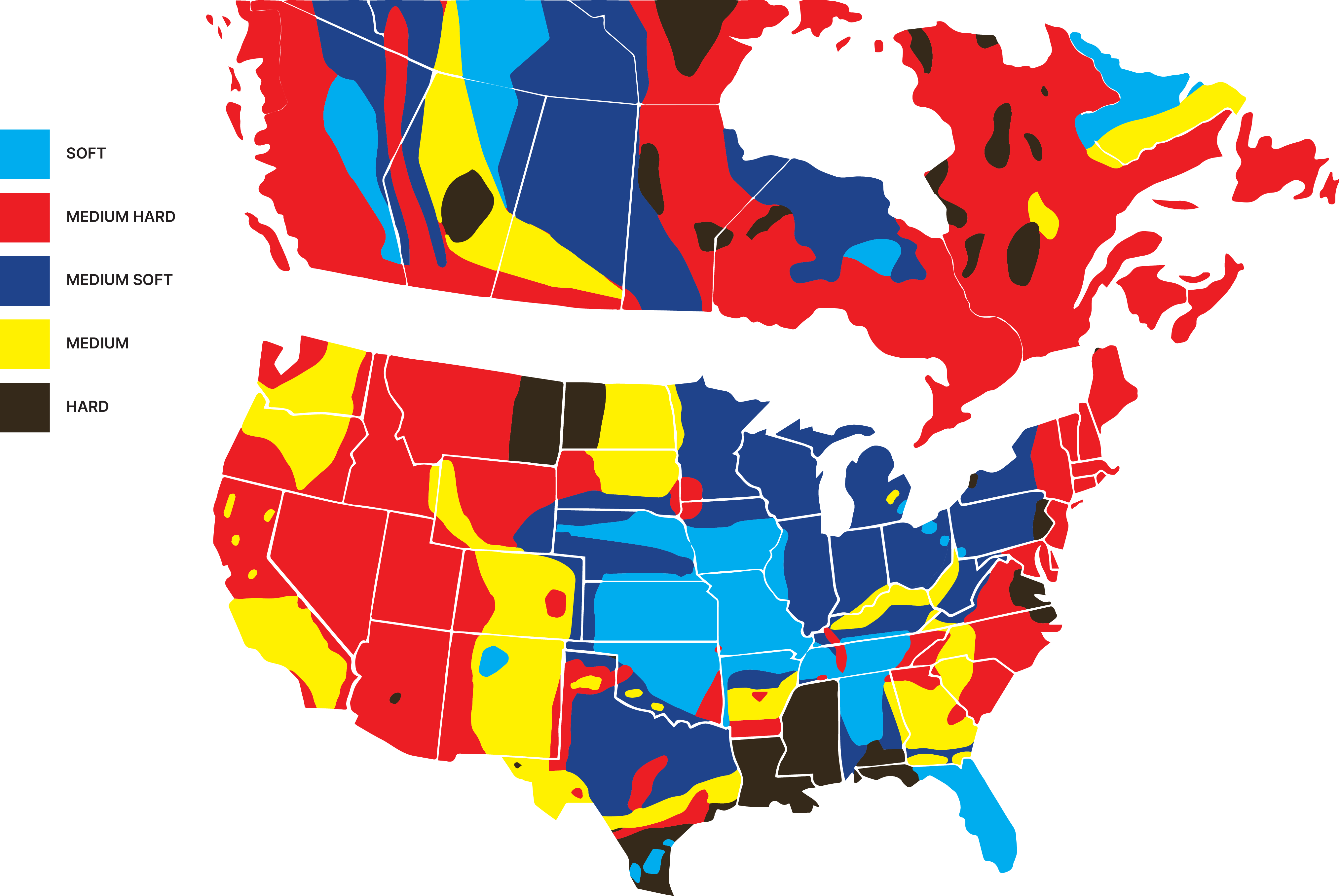

• AGGREGATE MAP

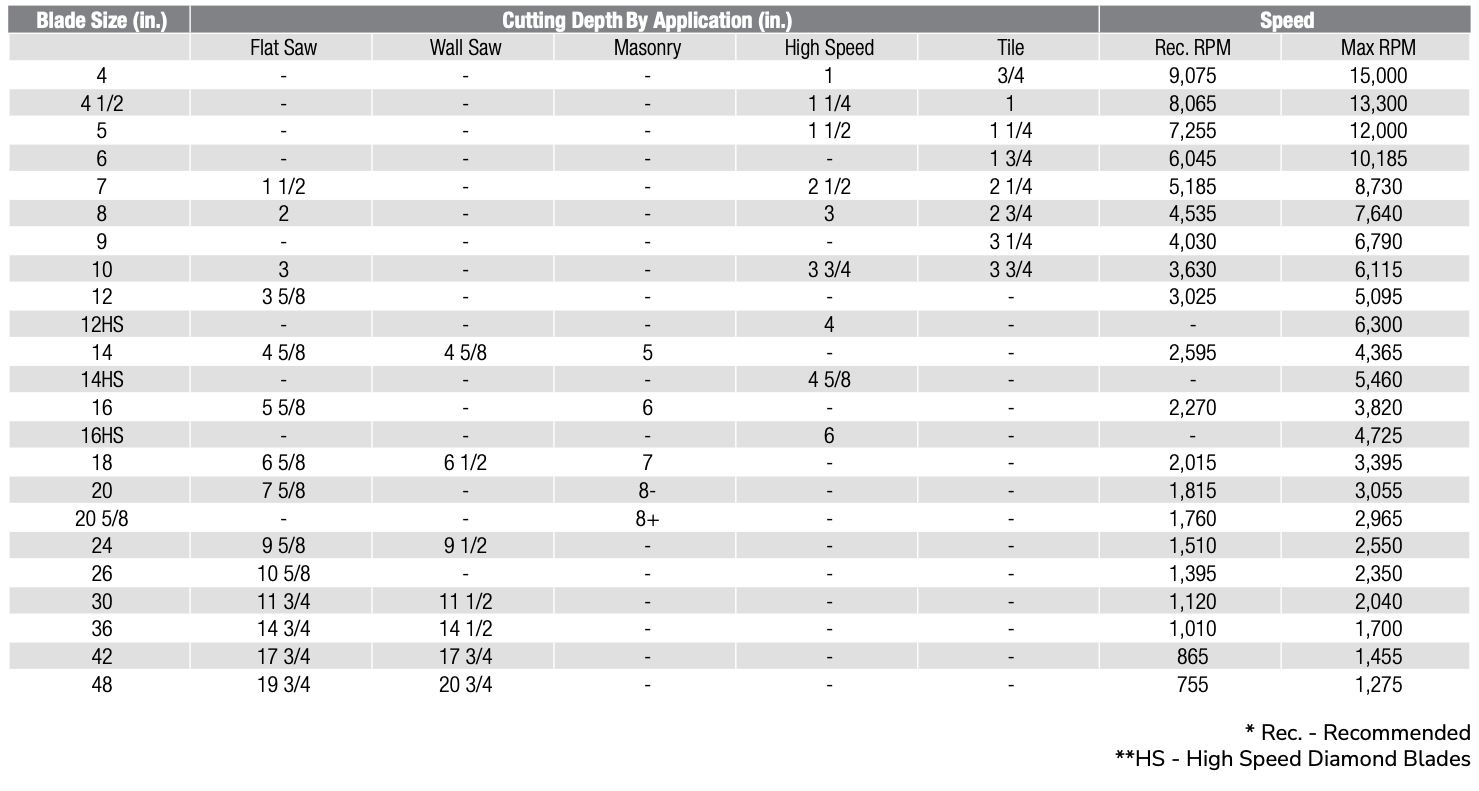

• DIAMOND BLADE CUTTING DEPTH AND SPEED

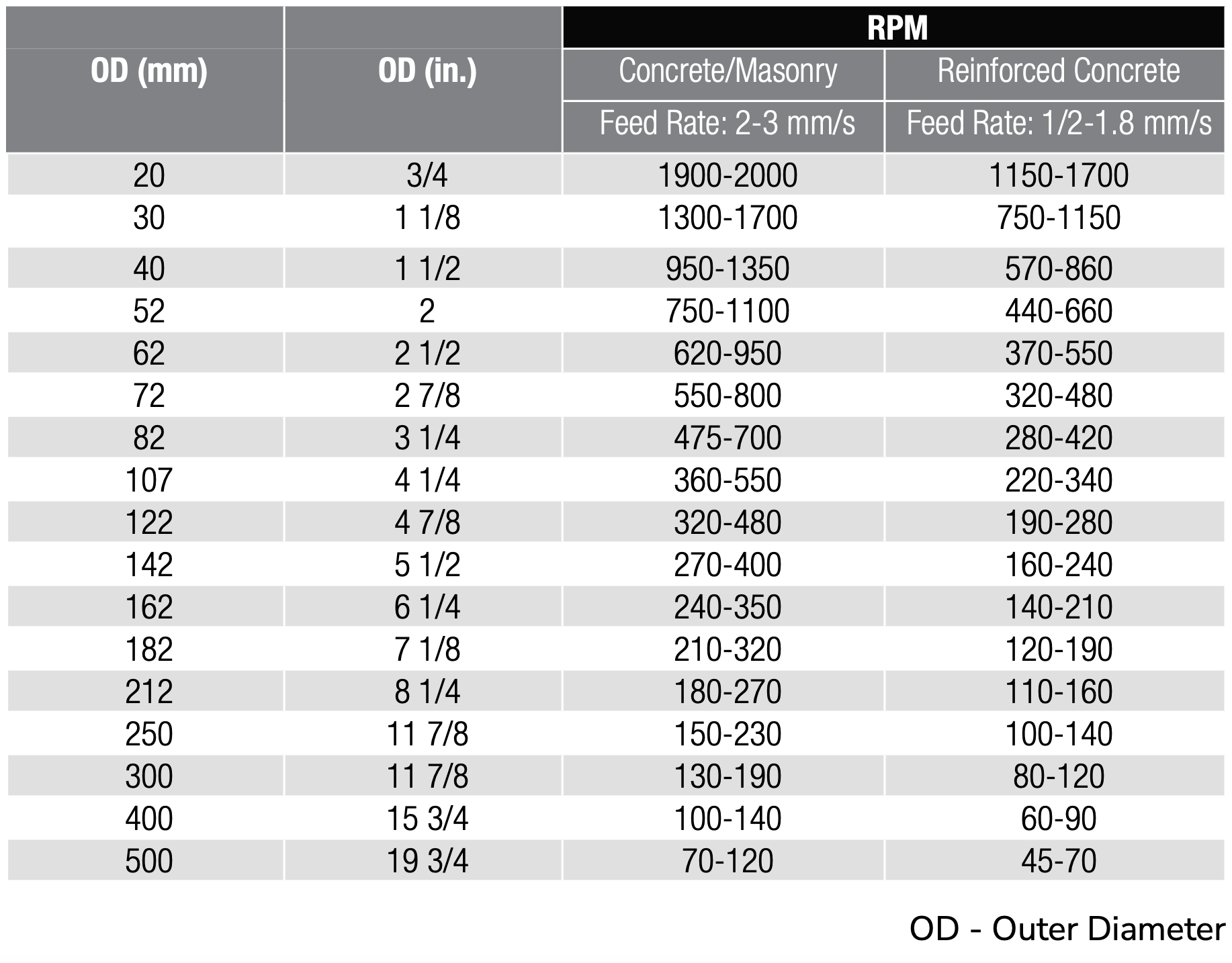

• CORE BIT RPM CHART

• DIAMOND BLADE SEGMENT/RIM SAMPLE CHART

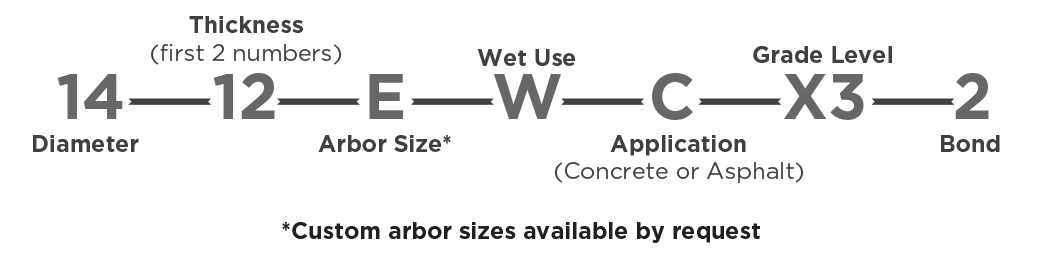

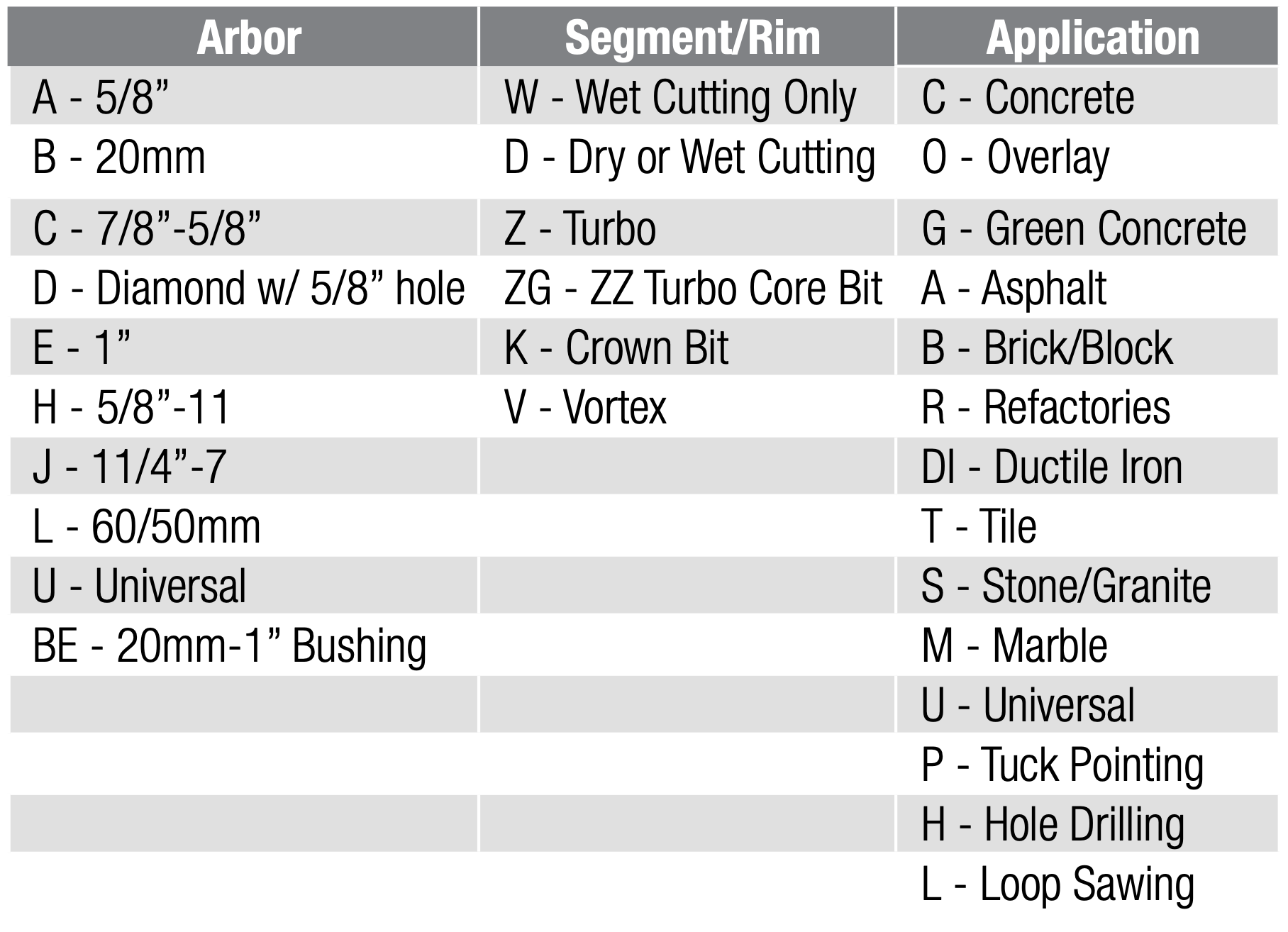

• PART NUMBER CHART

• BOND/SEGMENT HARDNESS

• DESCRIPTION OF ICONS

• BLADE TROUBLESHOOTING

Diamond blades contain industrial-grade diamond embedded in segments or rims on their cutting edge. As the blade is used, the abrasive qualities of the material being cut (such as concrete) wears down the segment. Diamond crystals either get crushed or let loose as the metal matrix gets worn away, exposing new diamonds to continue the cutting.

The abrasive quality of the material being cut is a large factor in choosing the correct blade for a job. Harder, less abrasive materials such as cured concrete require a blade with a softer metal mix to ensure adequate erosion of the segment brings new diamond to the surface at an optimum rate.

Soft, abrasive materials such as green concrete and asphalt tend to wear down segments faster. Therefore, segments with a harder, more wear-resistant metal mix in the segment, provide longer blade life and overall better performance.

Abrasive materials tend to erode the metal core, or center, of diamond blades causing undercutting. Undercutting tends to be concentrated on part of the core that attaches to the segment. If undercutting is excessive, it can cause segment loss and damage the blade. Diamond Vantage offers 3 types of undercut protection which reduce abrasive slurry accumulation beneath the segments to provide extended blade life.

Segments come in different heights. The total segment height is not as important as the diamond depth – the portion of the segment that contains diamonds. The diamond depth combined with diamond concentration and quality determines the overall performance value of the blade.

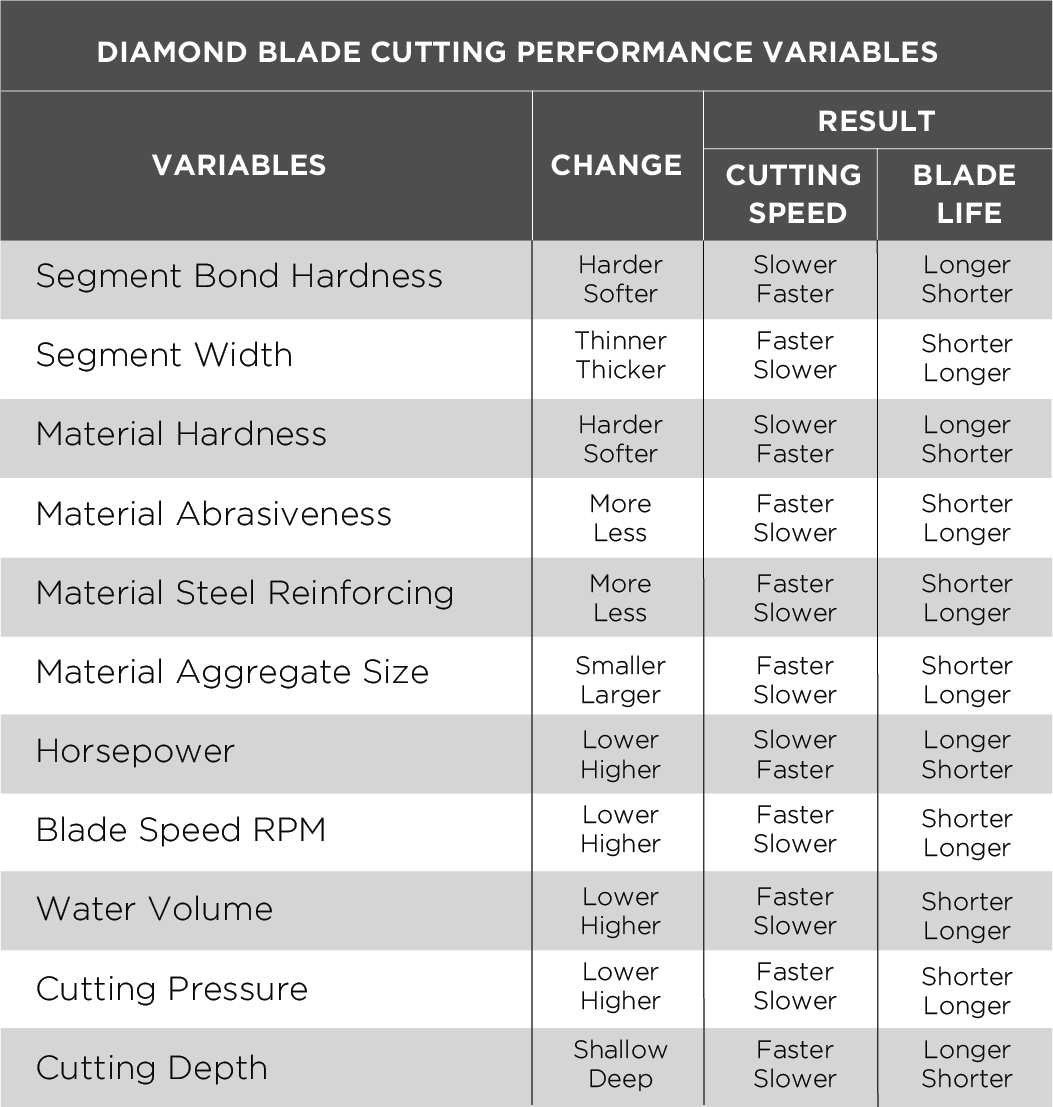

The accompanying chart shows the effect different variables have on a diamond blade cutting speed and blade life.

WHAT IS THE MATERIAL?

Ex. Brick, block, combination, green concrete, cured

concrete, asphalt etc.

WHAT IS THE CUTTING METHOD?

Wet and dry?

WHAT KIND OF EQUIPMENT IS BEING USED?

Ex. High speed hand held saw, masonry table type

saw, walk behind saw (low or high HP), hand held

power tool

HOW DEEP IS THE CUT?

Use proper blade diameter for depth required.

Remember, a 5” cut requires a 14” blade

HOW BIG IS THE JOB?

Higher quality blades are more economical to use

The actual cutting depth may vary depending on a number of factors, including the exact blade

diameter,

the exact flange diameter, saw components, etc.

Warning: Operating at greater than the max RPM can cause blade damage, which may cause injury.

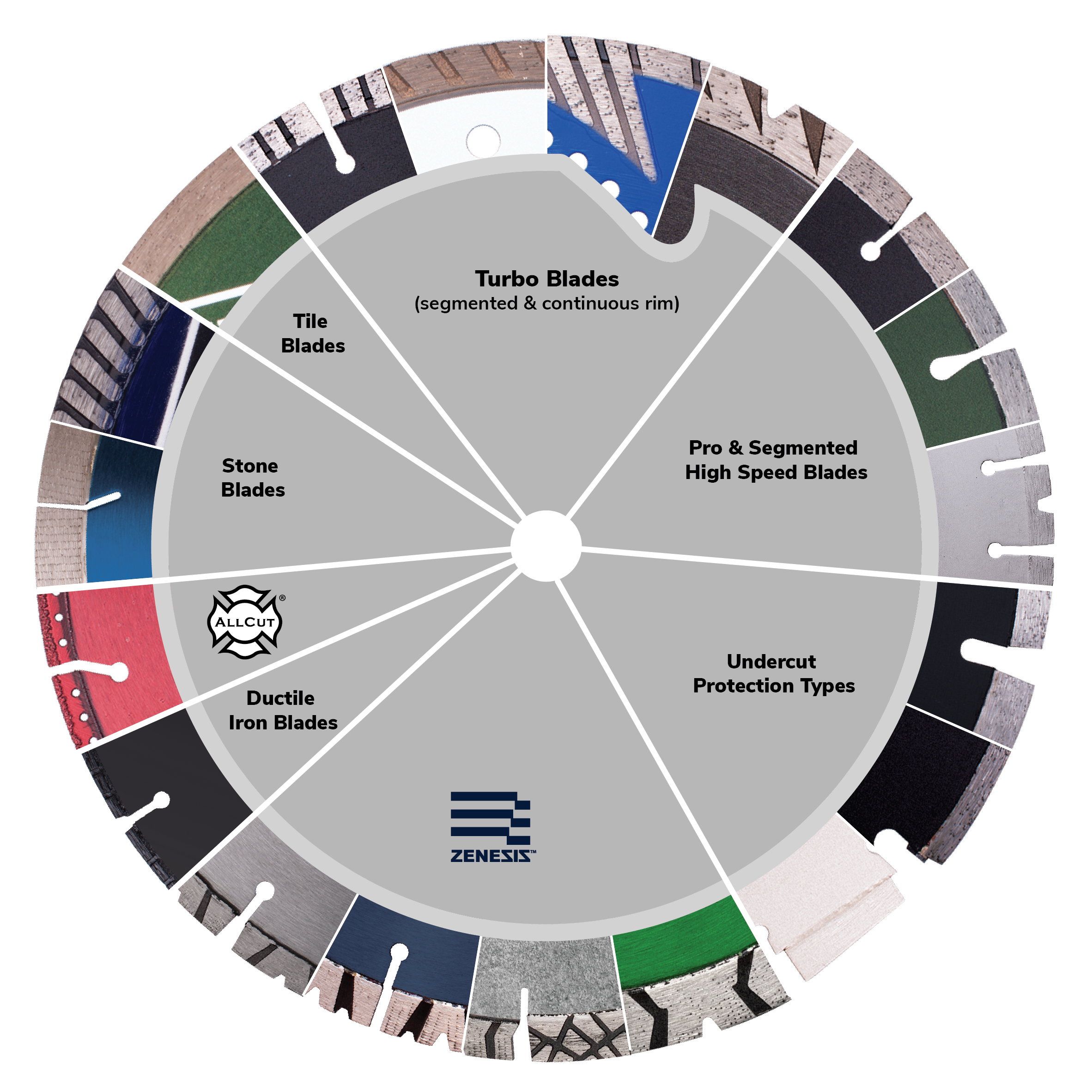

Diamond blades come in many different segment and rim configurations. This chart may help to show the various types of products available and to simplify, for the user, the selection of what will best serve the desired application. The actual application will determine the final product specification, shape, and size.

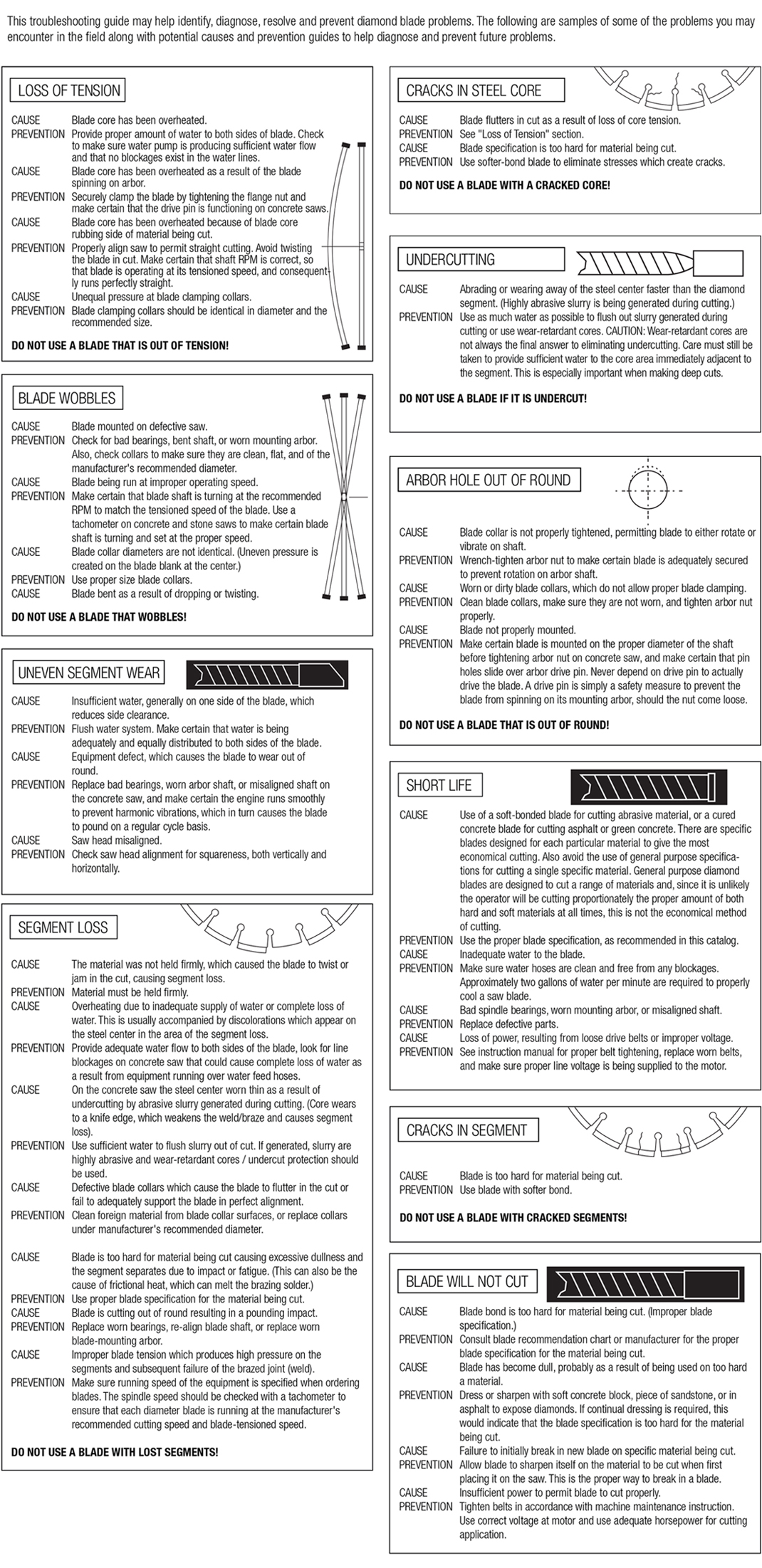

This troubleshooting guide may help identify, diagnose, resolve and

prevent diamond blade problems. The following are samples of some of the

problems you may encounter in the field along with potential causes and prevention guides to

help diagnose and prevent future problems.